We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

Pagid RSL Compound Overview

The compounds used in the creation of PAGID Racing’s brake pads have a very high content of non-ferrous (ceramic) materials, and this provides incredible thermal insulation and very high heat resistance and low heat conductivity. This reduces the heat transfer to the caliper (up to a massive 60 °C) preventing boiling of the brake fluid.

However, not all compounds are designed to meet the same temperature requirements – each motorsport discipline has its own set of conditions that a brake pad must meet. There is no “one size fits all” approach, which is why PAGID Racing have a multitude of brake pad compounds which are continually subjected to the most challenging real-world tests.

Not only does this guarantee consistent performance and durability, but it also results in improved vehicle safety, minimised wear of the pad-rotor system, and a reduced impact on the environment.

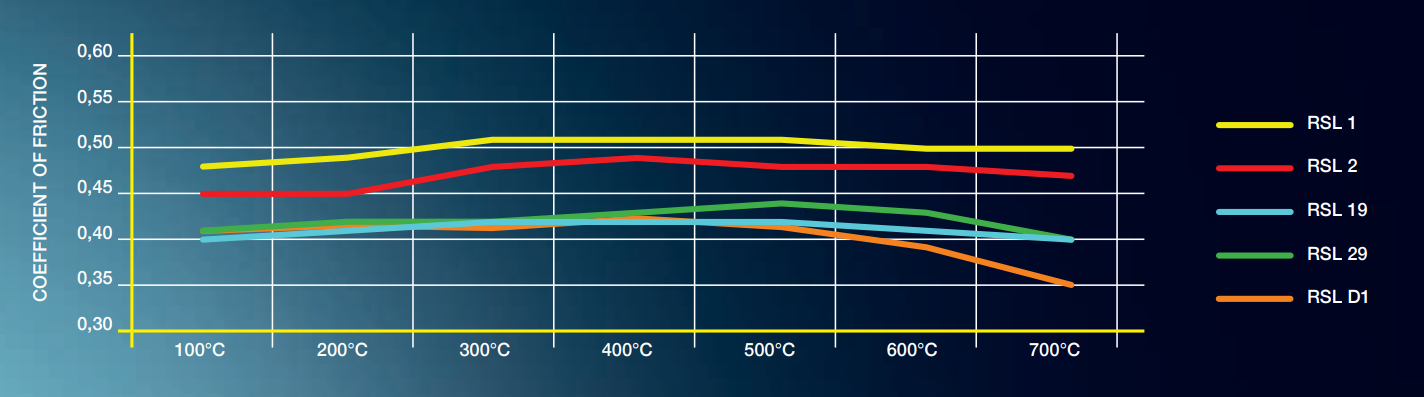

RSL Friction vs Temperature

PAGID Racing RSL – Endurance at the core

PAGID Racing’s RSL compound provides excellent braking consistency across a number of temperature ranges, and is typically used in endurance style racing such as GT championships, Touring Cars, GTE/GT3 and due to its good modulation and high friction capabilities, it can also be used in sprint series racing.

The RSL range is available in five different compounds; RSL 1, RSL 2, RSL 19, RSL 29 and RSL D1 - please see the table below for a list of the applications and benefits that each compound provides.

Compound |

Key Features |

Application Range & Description |

|

RSL 1 is a low metallic resin bonded material containing steel and aramid fibers with high heat resistance. It maintains a constant friction level over a wide range of temperatures. Its low wear rate and disc friendliness make this material appropriate for endurance races. |

|

RSL 2 is based on the RSL 1 compound but has been further improved in terms of pad and disc life as well as friction stability vs. temperature. It is a low metallic resin bonded material containing steel and aramid fibers. Furthermore, it maintains a constant friction level over a wide range of temperatures. |

|

RSL 19 is a low metallic resin bonded material containing steel and aramid fibers. It maintains a constant friction level across a broad range of temperatures. The material features very good modulation and release characteristic. |

|

RSL 29 features very good modulation and release characteristics. It is a low metallic resin bonded material containing steel and aramid fibers. The friction level of the material maintains constant at a low-medium level. Another advantage is the easy bedding in behaviour. |

|

Specifically developed for rear axle applications. The RSL D1 compounds provide benefits in terms of vehicle stability during the turn-in stage and unloading the front axle regarding pad wear. |

To view the full range of Pagid Racing RSL compound brake pads, please click here.

0 Comment(s)